[caption id="attachment_2775" align="aligncenter" width="1014"] Our daily starch. File Photo[/caption]

Starch or amylum is a polymeric carbohydrate consisting of numerous glucose units joined by glycosidic bonds. This polysaccharide is produced by most green plants as energy storage. It is the most common carbohydrate in human diets and is contained in large amounts in staple foods like potatoes, wheat, maize (corn), rice, and cassava. Pure starch is a white, tasteless and odorless powder that is insoluble in cold water or alcohol. It consists of two types of molecules: the linear and helical amylose and the branched amylopectin. Depending on the plant, starch generally contains 20 to 25% amylose and 75 to 80% amylopectin by weight. Glycogen, the glucose store of animals, is a more highly branched version of amylopectin. In industry, starch is converted into sugars, for example by malting, and fermented to produce ethanol in the manufacture of beer, whisky and biofuel. It is processed to produce many of the sugars used in processed foods. Mixing most starches in warm water produces a paste, such as wheatpaste, which can be used as a thickening, stiffening or gluing agent. The biggest industrial non-food use of starch is as an adhesive in the papermaking process. Starch can be applied to parts of some garments before ironing, to stiffen them.

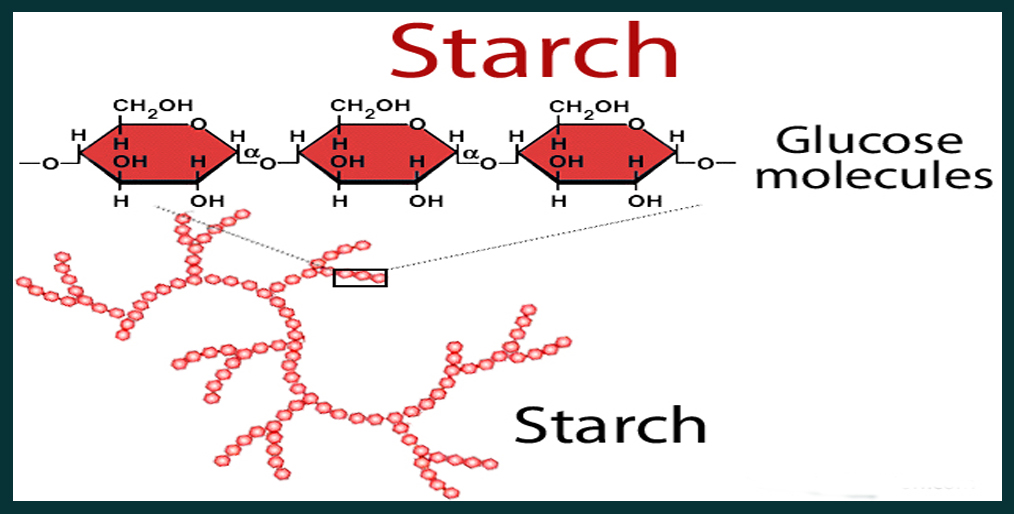

Starch structure and function: Chemically, starches are polysaccharides that consist of repeating glucose units. Starch molecules have one of two molecular structures: a linear structure, known as amylose; and a branched structure, known as amylopectin. Amylose and amylopectin associate through hydrogen bonding and arrange themselves radially in layers to form granules. Starches from different sources vary from one another in the following ways - each of which may affect performance:

Granule size and shape: Starch granules come in a wide variety of sizes ranging from three microns to over 100 microns. Wheat starch, for example, has a distribution of both large and small granules while corn-starch has a narrow distribution of rather large granules.

Amylose: All starches are composed of varying proportions of amylose and amylopectin. The ratio varies not only among the different types of starch, but also among the many plant varieties within a type. Waxy starches are those that have no more than 10 percent amylopectin. Standard wheat and corn starches contain 25-to-28 percent of amylose and 72-to-75 percent of amylopectin, not a big difference for this specific parameter. Other variations also exist in starches. In general, most such variations consist of the presence of non-starch components in the granule (or close to), such as lipids or protein. Those elements can highly influence gelatinization, even at low concentration.

[caption id="attachment_2776" align="aligncenter" width="1014"]

Our daily starch. File Photo[/caption]

Starch or amylum is a polymeric carbohydrate consisting of numerous glucose units joined by glycosidic bonds. This polysaccharide is produced by most green plants as energy storage. It is the most common carbohydrate in human diets and is contained in large amounts in staple foods like potatoes, wheat, maize (corn), rice, and cassava. Pure starch is a white, tasteless and odorless powder that is insoluble in cold water or alcohol. It consists of two types of molecules: the linear and helical amylose and the branched amylopectin. Depending on the plant, starch generally contains 20 to 25% amylose and 75 to 80% amylopectin by weight. Glycogen, the glucose store of animals, is a more highly branched version of amylopectin. In industry, starch is converted into sugars, for example by malting, and fermented to produce ethanol in the manufacture of beer, whisky and biofuel. It is processed to produce many of the sugars used in processed foods. Mixing most starches in warm water produces a paste, such as wheatpaste, which can be used as a thickening, stiffening or gluing agent. The biggest industrial non-food use of starch is as an adhesive in the papermaking process. Starch can be applied to parts of some garments before ironing, to stiffen them.

Starch structure and function: Chemically, starches are polysaccharides that consist of repeating glucose units. Starch molecules have one of two molecular structures: a linear structure, known as amylose; and a branched structure, known as amylopectin. Amylose and amylopectin associate through hydrogen bonding and arrange themselves radially in layers to form granules. Starches from different sources vary from one another in the following ways - each of which may affect performance:

Granule size and shape: Starch granules come in a wide variety of sizes ranging from three microns to over 100 microns. Wheat starch, for example, has a distribution of both large and small granules while corn-starch has a narrow distribution of rather large granules.

Amylose: All starches are composed of varying proportions of amylose and amylopectin. The ratio varies not only among the different types of starch, but also among the many plant varieties within a type. Waxy starches are those that have no more than 10 percent amylopectin. Standard wheat and corn starches contain 25-to-28 percent of amylose and 72-to-75 percent of amylopectin, not a big difference for this specific parameter. Other variations also exist in starches. In general, most such variations consist of the presence of non-starch components in the granule (or close to), such as lipids or protein. Those elements can highly influence gelatinization, even at low concentration.

[caption id="attachment_2776" align="aligncenter" width="1014"] Starchy foods. File Photo[/caption]

Corn: Four classes of corn-starch exist. Common corn-starch has 25 percent amylose, while waxy maize is almost totally composed of amylopectin. The two remaining corn starches are high-amylose cornstarches; one has 50-to-55 percent amylose, while the second has 70-to-75 percent. Granule size ranges between 15 microns and 20 microns, quite a narrow distribution.

Potato: Potato starch has about 20 percent amylose. Its granules range in size from 15-to-75 microns, quite a large distribution.

Rice: Common rice starch has an amylose: amylopectin ratio of about 20:80, while waxy rice starch has only about two percent amylose. Both varieties have small granule sizes ranging from 3-to-8 microns.

Tapioca: Tapioca starch has 15-to-18 percent amylose. Tapioca granules are smooth, irregular spheres with sizes ranging from 5-to-25 microns (large distribution).

Wheat: Wheat starch has an amylose content of around 25 percent. Its granules are relatively thick at 2-to-15 microns. Starch experts universally agree that starch structure and composition affect performance. However, a direct correlation is not always obvious, and we should consider changes in several traits to explain main differences between starch sources. A review of what is currently known about how structure and composition affect performance follows. But first, here is a brief review of what happens during starch gelatinization during pelleting. When starch enters the conditioner, water penetrates the starch granule from the outside inward until the granule is fully hydrated. Once hydrated, the hydrogen bonding between the amylose and the amylopectin maintains the integrity of the granule and it begins to swell from the center. Once gelatinized, the swollen granules may increase the viscosity of the dispersion creating in most cases a good pellet, or when gelatinization is not under control, blocking the dye.

Granule size and structure: Large starch granules tend to build higher viscosity, but the viscosity is delicate because the physical size of the granule makes it more sensitive to shear. But bringing viscosity is not necessarily bad in pelleting. It can provide extra binding capacity, and that's what we ask of starch-based raw materials. Thus, more than the granule size, the narrow or large distribution of granule sizes has even more influence on gelatinization. Wheat starch, for example, has a bimodal distribution of both small and large granules, and those granules will, therefore, gelatinize at different moments in the conditioner depending on heat and moisture available. This permits smooth and easy control of the gelatinization. Corn-starch has large granules with narrow distribution, and thus gelatinization happens all at once, which can create blockage in the dye.

[caption id="attachment_2777" align="aligncenter" width="1014"]

Starchy foods. File Photo[/caption]

Corn: Four classes of corn-starch exist. Common corn-starch has 25 percent amylose, while waxy maize is almost totally composed of amylopectin. The two remaining corn starches are high-amylose cornstarches; one has 50-to-55 percent amylose, while the second has 70-to-75 percent. Granule size ranges between 15 microns and 20 microns, quite a narrow distribution.

Potato: Potato starch has about 20 percent amylose. Its granules range in size from 15-to-75 microns, quite a large distribution.

Rice: Common rice starch has an amylose: amylopectin ratio of about 20:80, while waxy rice starch has only about two percent amylose. Both varieties have small granule sizes ranging from 3-to-8 microns.

Tapioca: Tapioca starch has 15-to-18 percent amylose. Tapioca granules are smooth, irregular spheres with sizes ranging from 5-to-25 microns (large distribution).

Wheat: Wheat starch has an amylose content of around 25 percent. Its granules are relatively thick at 2-to-15 microns. Starch experts universally agree that starch structure and composition affect performance. However, a direct correlation is not always obvious, and we should consider changes in several traits to explain main differences between starch sources. A review of what is currently known about how structure and composition affect performance follows. But first, here is a brief review of what happens during starch gelatinization during pelleting. When starch enters the conditioner, water penetrates the starch granule from the outside inward until the granule is fully hydrated. Once hydrated, the hydrogen bonding between the amylose and the amylopectin maintains the integrity of the granule and it begins to swell from the center. Once gelatinized, the swollen granules may increase the viscosity of the dispersion creating in most cases a good pellet, or when gelatinization is not under control, blocking the dye.

Granule size and structure: Large starch granules tend to build higher viscosity, but the viscosity is delicate because the physical size of the granule makes it more sensitive to shear. But bringing viscosity is not necessarily bad in pelleting. It can provide extra binding capacity, and that's what we ask of starch-based raw materials. Thus, more than the granule size, the narrow or large distribution of granule sizes has even more influence on gelatinization. Wheat starch, for example, has a bimodal distribution of both small and large granules, and those granules will, therefore, gelatinize at different moments in the conditioner depending on heat and moisture available. This permits smooth and easy control of the gelatinization. Corn-starch has large granules with narrow distribution, and thus gelatinization happens all at once, which can create blockage in the dye.

[caption id="attachment_2777" align="aligncenter" width="1014"] Starch reform. File Photo [/caption]

Temperature: Gelatinization temperature windows can vary with raw materials. Wheat is the first starch to get, thus making it an easy binder for pelleting. Barley starch is also quite easy to pelletize. However, corn-starch only starts to gelatinize at 70-to-72°C where other polymerization (see paragraph on lipids and proteins) can occur.

How to characterize starch in pelleting: Starch experts universally agree that starch structure and composition affect performance. However, a direct correlation is not always obvious, and we should consider changes in several traits to explain main differences between starch sources. A review of what is currently known about how structure and composition affect performance follows. But first, here is a brief review of what happens during starch gelatinization during pelleting: When starch enters the conditioner, water penetrates the starch granule from the outside inward until the granule is fully hydrated. Once hydrated, the hydrogen bonding between the amylose and the amylopectin maintains the integrity of the granule and it begins to swell from the center. Once gelatinized, the swollen granules may increase the viscosity of the dispersion creating in most cases a good pellet, or when gelatinization is not under control, blocking the dye.

Lipids: Lipids are known to inhibit granule swelling. Maize contains approximately twice as much lipid as wheat and it can be one of the elements affecting the ease with which wheat starch gelatinizes compared to maize.

Protein: During gelatinization, if protein is directly available in the near environment of the starch granules, then this protein can get associated with the surface of the granule (polymerization). This creates a protein starch polymer, which increases the viscosity of the feed. This is the case when one uses corn gluten meal in a feed formulation, which is rich in protein and starch. Protein and starch will recombine during gelatinization and generate a plastic mass into the dye, leading most often to blockages.

Source: Online/SZK

Starch reform. File Photo [/caption]

Temperature: Gelatinization temperature windows can vary with raw materials. Wheat is the first starch to get, thus making it an easy binder for pelleting. Barley starch is also quite easy to pelletize. However, corn-starch only starts to gelatinize at 70-to-72°C where other polymerization (see paragraph on lipids and proteins) can occur.

How to characterize starch in pelleting: Starch experts universally agree that starch structure and composition affect performance. However, a direct correlation is not always obvious, and we should consider changes in several traits to explain main differences between starch sources. A review of what is currently known about how structure and composition affect performance follows. But first, here is a brief review of what happens during starch gelatinization during pelleting: When starch enters the conditioner, water penetrates the starch granule from the outside inward until the granule is fully hydrated. Once hydrated, the hydrogen bonding between the amylose and the amylopectin maintains the integrity of the granule and it begins to swell from the center. Once gelatinized, the swollen granules may increase the viscosity of the dispersion creating in most cases a good pellet, or when gelatinization is not under control, blocking the dye.

Lipids: Lipids are known to inhibit granule swelling. Maize contains approximately twice as much lipid as wheat and it can be one of the elements affecting the ease with which wheat starch gelatinizes compared to maize.

Protein: During gelatinization, if protein is directly available in the near environment of the starch granules, then this protein can get associated with the surface of the granule (polymerization). This creates a protein starch polymer, which increases the viscosity of the feed. This is the case when one uses corn gluten meal in a feed formulation, which is rich in protein and starch. Protein and starch will recombine during gelatinization and generate a plastic mass into the dye, leading most often to blockages.

Source: Online/SZK

Comment Now