The traditional way of manufacturing a roller mill chassis is to use either welded steel or cast iron. Instead, Imas presents Polymer Base Construction® with the major advantage of a superior vibration-damping ability, which provides higher reliability and extended long-term durability for roller mills…

Imas R&D and Engineering team achieved to develop the unconventional roller mill chassis construction material, namely Polymer Base Construction®, which has been officially released for worldwide customers since 2023, as being the first example of using polymeric composites in the milling industry.

Due to its superior vibration-damping ability compared to steel and cast iron, Polymer Base Construction® helps provide a smooth, efficient, and trouble-free operation for roller mills.

Continuously following the latest technologies and industry trends, Imas R&D and Engineering team has been working on polymeric composite chassis design since 2020, and has now successfully completed all research, laboratory testing, design development, prototype testing, and patenting processes.

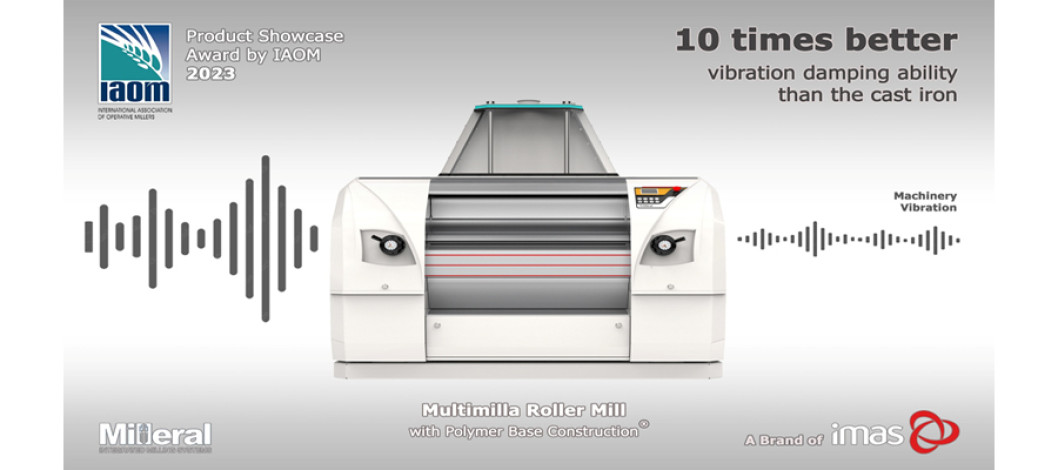

The innovative chassis design by Imas has already received the ‘Product Showcase 2023’ award by IAOM (International Association of Operative Millers), during the IAOM USA Conference and Expo between April 17-21 in Minnesota, USA.

Polymeric Composites: A Game Changer in the Industry

Polymeric composites can be simply described as combinations of polymers and various reinforcements, in order to get new features out of them for specific applications. The industry keeps curiously looking for creating new variations and utilizations of polymeric composites for different uses…

‘Metal replacement’ has become an emerging concept in the industry, which can be defined as the substitution of metals with materials with superior abilities, such as high-performance polymer composites. They are mostly preferred due to their advantages of high strength-to-weight ratio, lightweight, corrosion resistance, design flexibility, and enhanced performance in specific applications.

Polymeric composites have already been used in many industries, including automotive, aviation, defense, construction, and energy. Moreover, they are being used as a replacement for steel, especially in high-precision industrial processes, ie. CNC machining, robotics, etc., due to their superior abilities of high resistance, vibration damping, and thermal stability.

Machinery vibration, which occurs naturally during the operation of any machine, has some important hidden threads.

In the short term, high machinery vibration levels can have a disruptive effect on the sensitive operating adjustments of machines, which may also lead to inconsistency in the process and product quality.

In the long term, machinery vibration can cause failures that may result in shortened machine life, through the continuous effect and damage to the parts and components (bearings, bearing housings, other moving parts).

Multimilla Roller Mill presents higher operational reliability and extended long-term durability with Polymer Base Construction®.

According to the tests and measurements carried out by Imas R&D and Engineering team, also with contributions of scientists from Konya Technical University and Necmettin Erbakan University, it is proven that Polymer Base Construction® actually has nearly 10 times better vibration damping ability than cast iron chassis, and even 20 times better than welded steel chassis.

Polymer Base Construction® has been implemented into the structural design of not only the Multimilla roller mill, also feed milling machines, including Viteral series flake roller, hammer mill, and pellet press.

About Imas R&D Center

IMAS R&D Center's mission is to set ‘New Engineering Standards’ in the grain and feed milling industries by continuously developing new machines, systems, and technological solutions.

IMAS is today among the Top 250 R&D Leaders of Türkiye since 2015, moreover, Top 10 R&D Leaders of Turkish Machinery Industry in all industrial segments in the last 4 years, according to the listing of companies having the most R&D budget by Turkishtime. IMAS is today the leader of the Turkish milling technologies industry to such a degree.

IMAS R&D Center works with a large team that also includes a university-industry partnership in Konya, Türkiye. THE IMAS R&D and Engineering team has also made important scientific contributions in the grain and feed processing industries, including experiments, articles, and publications.

Comment Now