The days of making flour from wheat by manual method have come to an end long ago. Over time, various machines and processes have gradually come to this place. In today's sophisticated flower milling industry, there are various aspects of sophisticated flower milling process. In short, this report will try to give some idea about these shots.

This process may vary slightly depending on the different industry, different company. Because, there are different machines of the same production running in the market. So it is normal for the process to be different in different machines. However, here is an attempt to highlight the general method.

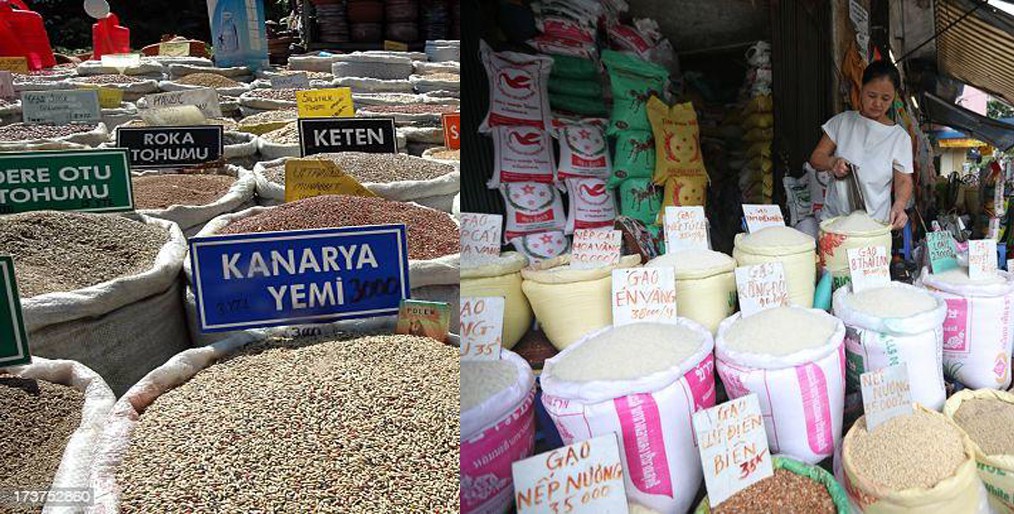

[caption id="attachment_7652" ]

Flour Milling Process Flow Pre-cleaning: After harvesting, the wheat can be mixed with straw, rope, stone, brick, dirt and other large impurities, which will damage the processing equipment or block the piping system. Therefore, initial cleaning process needs to be done before the wheat is deposited. Cleaning: To protect the quality of the flour and processing equipment before entering the milling process from temporary storage, pre-cleaned wheat needs further cleaning. This process uses a variety of methods such as screening, aspiration separation, magnetic separation, stone removal, wheat shaking, optical sorting, and so on. Features:

Picture: Collected[/caption] Flour Mill Solution For Steel Platform Structure Steel platform structure milling line is best installed in an open warehouse type building. These compact mills usually require two or three storey high. Features:

These are done by skilled engineering companies related to this subject. -SZK

Comment Now