Simplified project management and all-inclusive project scope

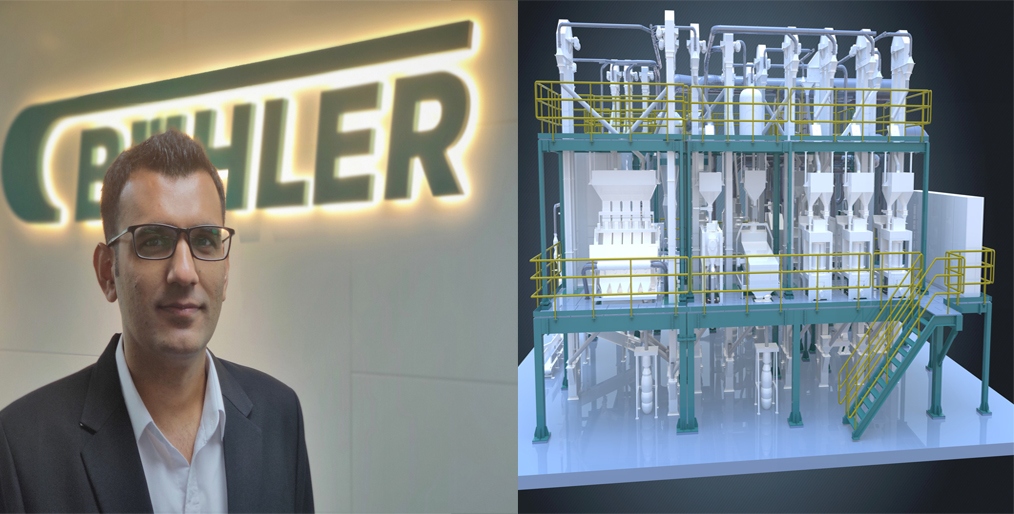

“The fundamental idea behind Uniline is that it is an all-inclusive rice mill delivered to your site”, explains Asif Abbas, Southeast Asia Regional Manager for Rice at Bühler. It includes all the equipment, the automation systems and the prefabricated steel structure needed to create a compact 2-level rice mill”. Uniline relies on an optimized concept developed by Bühler, which allows the Swiss company to achieve 15% energy savings in a 40% smaller footprint compared to conventional rice mills. Project speed is also increased, with commissioning taking place 18 weeks from the order with the support of local Bühler installation teams. “This all-inclusive package reduces the project’s complexity for rice millers, who will now have a single point of contact accountable for their entire mill,” adds Mr Abbas.

Suitable for greenfield projects or sustainability projects

The Uniline rice mill is already available for orders in Southeast Asia in three capacity options: 5 tons per hour (t/h), 8t/h and 10t/h. “Our primary market for Uniline are remote green field projects. We also anticipate interest from established rice millers who would be interested to add new dedicated lines for organic or local rice sub-varieties.” Uniline offers a high-level of automation, quality control, and food-safety, making it suitable for operations aiming at export markets.

For more information about Bühler’s Uniline, please visit: https://www.feeding.asia/bangladesh

Source: Email/SZK

Simplified project management and all-inclusive project scope

“The fundamental idea behind Uniline is that it is an all-inclusive rice mill delivered to your site”, explains Asif Abbas, Southeast Asia Regional Manager for Rice at Bühler. It includes all the equipment, the automation systems and the prefabricated steel structure needed to create a compact 2-level rice mill”. Uniline relies on an optimized concept developed by Bühler, which allows the Swiss company to achieve 15% energy savings in a 40% smaller footprint compared to conventional rice mills. Project speed is also increased, with commissioning taking place 18 weeks from the order with the support of local Bühler installation teams. “This all-inclusive package reduces the project’s complexity for rice millers, who will now have a single point of contact accountable for their entire mill,” adds Mr Abbas.

Suitable for greenfield projects or sustainability projects

The Uniline rice mill is already available for orders in Southeast Asia in three capacity options: 5 tons per hour (t/h), 8t/h and 10t/h. “Our primary market for Uniline are remote green field projects. We also anticipate interest from established rice millers who would be interested to add new dedicated lines for organic or local rice sub-varieties.” Uniline offers a high-level of automation, quality control, and food-safety, making it suitable for operations aiming at export markets.

For more information about Bühler’s Uniline, please visit: https://www.feeding.asia/bangladesh

Source: Email/SZK

Comment Now