There are two methods for rice milling: chemical and mechanical. In chemical methods, the first is solvent extraction rice milling, which starts with rice bran oil softening the brown rice skin, and then slightly grinding white rice.

During the grinding process, rice bran oil and n-hexane mixture are constantly sprayed to form "drizzle" moisture, so as to obtain non-destructive low-temperature white rice, by-product rice bran oil and edible degreased rice bran. Another means of the chemical method is enzymatic hydrolysis, which uses the "biological tool" of fiber enzyme to cut the cortical fibers and break them apart so that the cortex of brown rice can be shed without grinding, and the task of rice-making can be completed. Pure brown rice separated from husk and coarse rice, the surface of the cortex contains more fiber, affecting the edible quality.

Rice milling is the process of removing the skin of brown rice to make it into the rice. Using mechanical action to remove the cortex is called mechanical rice milling; Soak brown rice in chemical solvent to soften the cortex, dissolve the cortex and the fat contained in the embryo in the solvent, and then grind the cortex through the lighter mechanical action, called chemical rice milling. But the latter is not used much in actual production. Mechanical rice milling relies on the friction and grinding of a rice milling machine to remove the skin.

The main working mechanism of the rice mill is the white room, which is the space where brown rice is rolled into white rice grains. There are rotating roller and local pressurizing devices (rice knife and press screen bar) inside, and the outer rice screen is used to remove the rice bran that is rolled from the rice grains. The pressure in the grinding room of the erasing-type rice mill (such as the iron roller rice mill) is relatively large.

The skin is mainly removed by the friction between the rice grains and the components of the rice mill and the relative motion between the rice grains and the rice grains. Among them, the air jet rice mill can constantly eude air flow from the roller to the grinding room to improve the grinding efficiency. Grinding type rice mill (such as sand roller rice mill) grinding indoor pressure is small, the roller has a higher circumferential speed, the main use of the surface of the sand roller emery numerous dense sharp sand blade, grinding effect and grinding skin.

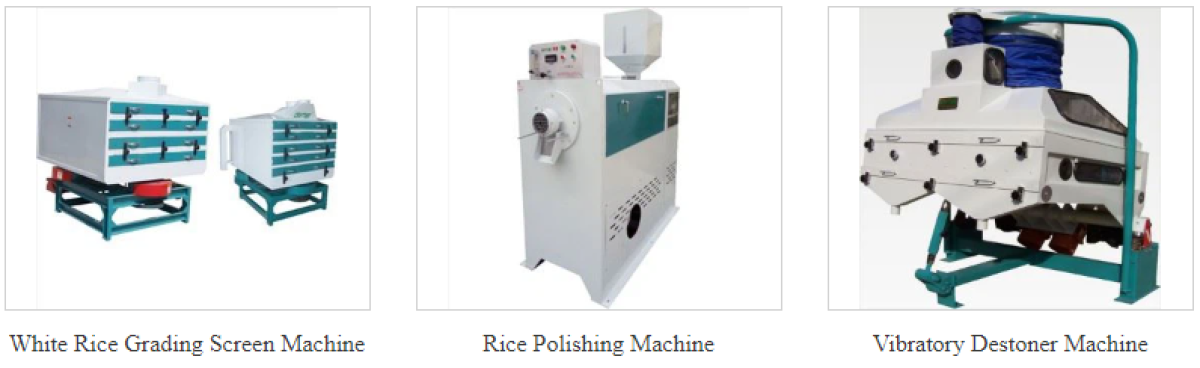

In order to reduce the pressure on rice grains during milling, rice from brown rice to high-precision rice is usually processed by two to four rice mills, and the skin is gradually rolled away. The ground white rice needs to be finished, including the separation of whole rice and broken rice with a screening machine. The finished rice according to the specifications is removed by the rice wiping machine from the bran crumbs adhering to the surface of the rice, and sometimes it also needs to be cooled by the suction effect of the rice cooling machine to become the finished rice.

Source:

Online/GFMM

Comment Now