The process of rice processing equipment consists of three stages: the rice pre-cleaning stage, the rice husking and separating stage, rice milling and finishing stage.

The process flow of the rice cleaning section is as follows: rice → initial cleaning → impurity removal (sand, stone, metal and paspalum, etc.) → clean grain.

The technical process of husking and separating is as follows: clean rice → husk separation → rough separation → clean rough.

The process flow of rice milling and finished product finishing section is as follows: clean rough → primary white grinding → secondary fine grinding → grading → cold rice → white rice grading → polishing → white rice grading → secondary polishing → roller selection → color selection → rice mixing → metering and packaging → finished product storage.

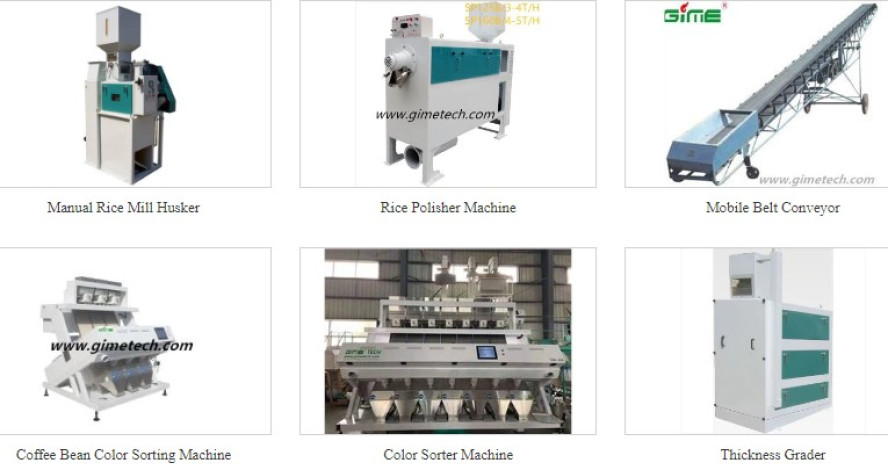

Rice processing equipment mainly consists of a miscellaneous grain cleaning machine, stone removal machine, rice huller, separator, rice milling machine, classifier, big beige separator, polishing machine, conveyor and so on.

1, specific gravity to the stone machine: is a kind of use of granular materials (rice, brown rice, rice, wheat, etc.) and minerals (mainly side-by-side stone, etc.) density and suspension speed is different, and with the help of mechanical wind and a certain track for reciprocating motion of the screen surface minerals separated from the particle material impurity removal equipment. It is an essential key equipment in rice processing technology.

2. Hulling machine: a grain processing machine for removing the hulls of rice and making brown rice. It can remove the rice husk, and reduce the rice grain burst waist and skin damage, as far as possible to keep brown rice intact. It is mainly composed of a hopper feeding device, head device, husk separation chamber, gear transmission, frame and so on.

3. Rice milling machine: mainly composed of a fixed wrench, tightened nut wrench, brush, hopper, grinding wheel, wire brush and so on. The brown rice is peeled and whitened by the mechanical force generated by mechanical equipment, which is called a rice mill.

4, polishing machine: also known as grinding machine, often used as mechanical grinding, polishing and waxing. Its working principle is the motor drive installed in the polishing machine sponge or wool throwing disc high-speed rotation, due to the joint action of throwing disc and polishing agent and friction with the surface to be thrown, and then can achieve the removal of paint pollution, oxidation layer, shallow marks.

5, color separator: according to the difference in the optical characteristics of the material, the use of photoelectric detection technology to automatically sort out the different color particles in the particle material. At present, color separators are used in bulk materials or packaging industrial products, food quality detection and classification field.

6, packaging machine: it is a kind of machine to pack the product, plays the role of protection and beauty.

Source:

Online/GFMM

Comment Now