Photo: Collected

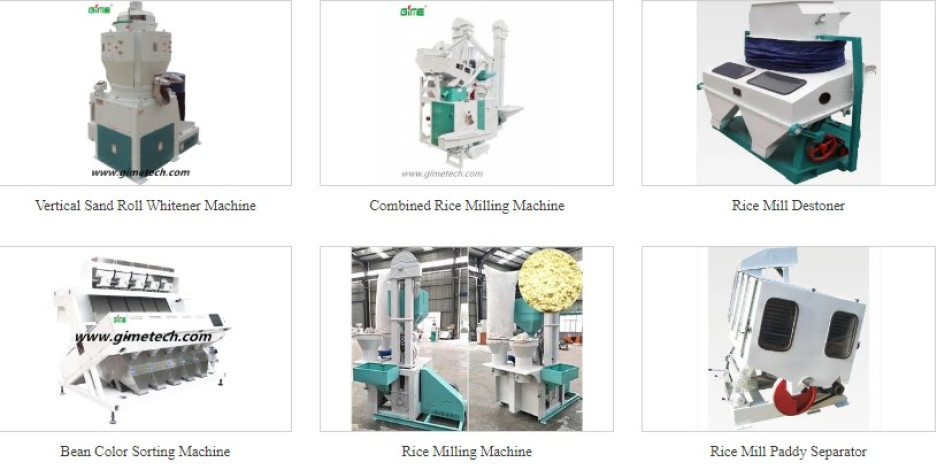

The complete set of rice processing equipment is a kind of machine equipment that can replace the artificial processing of rice, and the rice processed by this equipment is much better than the artificial in both quality and quantity. In fact, this is very much related to the working principle of the equipment, in order to help you better understand this content.

Rice processing equipment is small flour machinery composed of power, feeding, milling and separation systems. The mating surface at the lower end of the inner and outer grinding head is cylindrical, and the upper part of the grinding head is composed of two centripetal ball bearings as two main supporting points, and the cylinder at the lower end of the inner and outer grinding head as rotation auxiliary supporting points, and the clearance of the inner and outer grinding head is adjusted by the axial movement of the inner grinding head.

The ground rice falls directly from the gap between the grinding head to the bottom through the rack, and the flour is separated from the bran by the brush and the bottom which can adjust the gap. The new complete equipment for rice processing has the advantages of simple structure, good processing and installation technology, small volume, light noise, convenient operation and use, and not easy to produce excessive torque or bond flour.

The tooth roller of the small flour machine for grinding grain is characterized by the triangular strip roller teeth that are parallel to the axis on the cylindrical surface of the roller. The rice processing equipment of the utility model has the advantages of high crushing strength, high grinding efficiency, and obvious energy-saving effect, and the roller is not easy to damage.

The body of complete equipment for rice processing is non-casting material, that use of steel plate welding, in addition to the special cutting function, the machine is synchronically equipped with a classification device, and the crushed material by airflow, through the classification device and collection, classification device usually replaces the screen of the crushing equipment, can simultaneously complete the micro grinding and micro powder separation two processing processes, one-time powder residue, The finished product rate is 100%.

Rice processing equipment can adjust the fineness of the product at any time, the fineness is uniform, and there is no need to increase the sifter screening equipment vulnerable parts are all made of special wear-resistant materials or hard alloy, good wear resistance, low-cost replacement of vulnerable parts, in line with the health standards of various products.

Complete sets of rice processing equipment can be cleaned at any time without stopping, which can ensure the normal operation and continuous function of rice processing equipment to automatically clean and crush a variety of different materials. Mixed evenly, once pulverized with no residue, and no cycle grinding can ensure the uniformity of the content of various components. The feeding size is not limited, no coarse crushing can be directly into the machine and can adapt to a variety of different water content of the material, with no need to match drying equipment.

Source:

Online/GFMM

Comment Now