[caption id="attachment_3190" align="aligncenter" width="1014"] Picture: Marema Coatings[/caption]

There are 20 years in the Polyurea market, Marema Química do Brasil Ltda. (Marema Coatings) is a chemical manufacturer and applicator of highly flexible elastomeric systems, called Polyureas (Elastomers bi-components - 100% solid elastic and waterproof membrane). With German formulation and production technology, we offer technologies in aromatic, aliphatic, polyaspartic, high and low pressure polyureas.

With two units in Rio Grande do Sul and others distributor in Brazil, Marema Coatings operates in 9 segments: Industrial, Infrastructure (Civil Construction), Sanitation, Automotive, Agricultural, Mining, Chemical & Petrochemical, Oil & Gas, Naval.

Marema Coatings technologies are designed to extend the life of metal, concrete, fiberglass, wood and other substrates.

Applied with a hot, high pressure proportioning machine, Polyureas are high technology designed to coat substrates that require robustness and longevity with higher waterproofing, anti-corrosion and anti-abrasion quality. Much in demand around the world, it is increasingly gaining ground in the markets of several countries, including Brazil, for its ability to reduce maintenance costs given its robustness that can last more than 50 years on the climate.

In the constant search for more technological innovations and production and application techniques, in 2016 Marema Coatings entered into a joint venture with the German company VIP Coatings, becoming part of a conglomerate of 7 factories around the world and expanding its line of products. Polyurea protective coatings and their application techniques, increasingly gaining the trust and approval of their customers and business partners. Recently signing another solid partnership with ALLMayer Silos do Brasil.

In the constant search for more technological innovations and production and application techniques, in 2016 Marema Coatings entered into a joint venture with the German company VIP Coatings, becoming part of a conglomerate of 7 factories around the world and expanding its line of products of Polyurea protective coatings and their application techniques, increasingly gaining the trust and approval of their customers and business partners. Recently signing another solid partnership with ALLMayer Silos do Brasil.

Marema Coatings QS PP 350 Polyurea systems have earned the approval and trust of ALLMayer Silos do Brasil, that uses them in silo bases and flow wheighting system, thus offering complete, high technology, quality, durability products and robustness always aiming at reducing maintenance costs, higher productivity and customer profitability, innovating in the agribusiness market.

QS PP 350 Polyurea Coating Application on Silos

1- Once the silo is exposed to the sun, the metal sheet generates condensation;

2- Infiltration caused by rain through the expansion joints; Often only the aeration system is not enough. These factors cause excess moisture resulting in decomposition, germination, or breakage of grain and seed. In these cases, these are discarded generating a large percentage of deficit and production losses.

The main focuses of grain loss are at the bottom of bulk warehouses, and silos, due to high humidity, the mass of the grain is compacted, generating fungi and preventing the proper functioning of equipment such as sweep auger or equipment unloading.

In addition, excess moisture compromises the storage structure, which eventually goes through the corrosion process, also contaminating grains and seeds, impairing the quality of the entire product. With the application of Marema Coatings QS PP 350 Polyurea at the base of the silos, water infiltration is prevented, the coating helps in the process of controlling the variables (temperature and humidity), solving these problems, preserving the quality of the silos grain and seed, crop productivity and, while still being an anti-corrosion coating, for the storage structure.

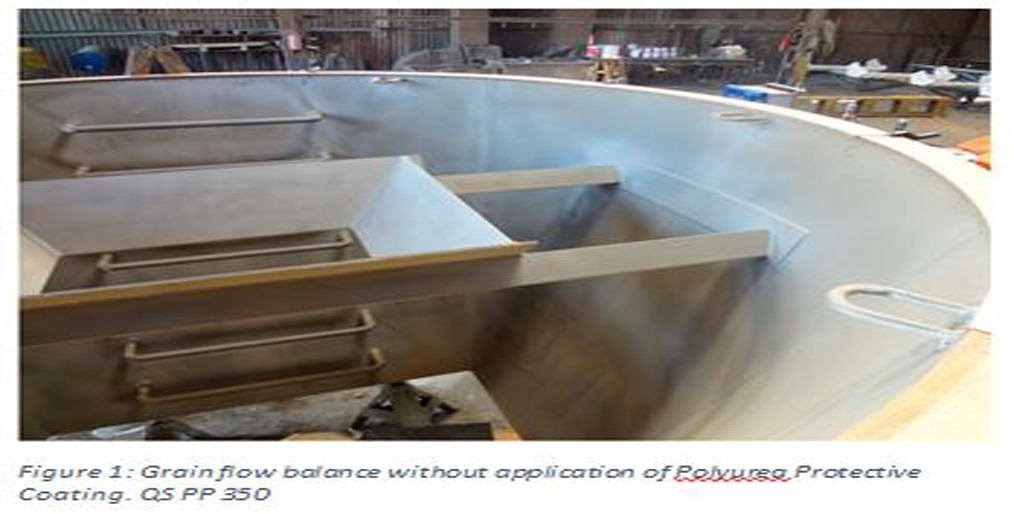

QS PP 350 Polyurea Protective Coating Application on flow wheighting system

Flow wheighting system are used for both loading and unloading grain on ships, trucks and wagons. Widely used in ports, calculates and indicates the subtotal and total flow (t / h) of the product transferred during the process.

In the case of ports, the passage of materials is continuous and large-scale, causing the grain, due to its impact and its abrasive content (rice, for example) to damage the metal substrate, wearing and puncturing it. This results in their frequent maintenance in a short time - we have cases where the substrate it's bored in 60 days of continuous use.

Large waste of both time and money are caused by this situation as the entire process needs to be interrupted to perform maintenance, leading to delays in loading or unloading the product.

Great costs are generated, of which we can mention:

1- Daily fine due to the fact that the ship is moored waiting for the cargo;

2- Delay in product billing;

3- Employees having to stop their activities;

4- Employees having to be relocated to perform the maintenance;

5- Maintenance by reworking the scales with the exchange of the metal substrate.

With the application of the QS PP 350 Polyuria (highly resistant to impact and sanding abrasion) the substrate is completely sealed, leaving it not in direct contact with the grain, thus preventing its early wear and thus considerably increasing its Shelf life - We have cases where we apply 13mm of the coating. After 4 years the expected wear would be 8 millimeters. During our quality control technical visit to the customer, wear of only 3mm was found, resulting in greatly reduced customer costs and increased productivity.

[caption id="attachment_3191" align="aligncenter" width="1014"]

Picture: Marema Coatings[/caption]

There are 20 years in the Polyurea market, Marema Química do Brasil Ltda. (Marema Coatings) is a chemical manufacturer and applicator of highly flexible elastomeric systems, called Polyureas (Elastomers bi-components - 100% solid elastic and waterproof membrane). With German formulation and production technology, we offer technologies in aromatic, aliphatic, polyaspartic, high and low pressure polyureas.

With two units in Rio Grande do Sul and others distributor in Brazil, Marema Coatings operates in 9 segments: Industrial, Infrastructure (Civil Construction), Sanitation, Automotive, Agricultural, Mining, Chemical & Petrochemical, Oil & Gas, Naval.

Marema Coatings technologies are designed to extend the life of metal, concrete, fiberglass, wood and other substrates.

Applied with a hot, high pressure proportioning machine, Polyureas are high technology designed to coat substrates that require robustness and longevity with higher waterproofing, anti-corrosion and anti-abrasion quality. Much in demand around the world, it is increasingly gaining ground in the markets of several countries, including Brazil, for its ability to reduce maintenance costs given its robustness that can last more than 50 years on the climate.

In the constant search for more technological innovations and production and application techniques, in 2016 Marema Coatings entered into a joint venture with the German company VIP Coatings, becoming part of a conglomerate of 7 factories around the world and expanding its line of products. Polyurea protective coatings and their application techniques, increasingly gaining the trust and approval of their customers and business partners. Recently signing another solid partnership with ALLMayer Silos do Brasil.

In the constant search for more technological innovations and production and application techniques, in 2016 Marema Coatings entered into a joint venture with the German company VIP Coatings, becoming part of a conglomerate of 7 factories around the world and expanding its line of products of Polyurea protective coatings and their application techniques, increasingly gaining the trust and approval of their customers and business partners. Recently signing another solid partnership with ALLMayer Silos do Brasil.

Marema Coatings QS PP 350 Polyurea systems have earned the approval and trust of ALLMayer Silos do Brasil, that uses them in silo bases and flow wheighting system, thus offering complete, high technology, quality, durability products and robustness always aiming at reducing maintenance costs, higher productivity and customer profitability, innovating in the agribusiness market.

QS PP 350 Polyurea Coating Application on Silos

1- Once the silo is exposed to the sun, the metal sheet generates condensation;

2- Infiltration caused by rain through the expansion joints; Often only the aeration system is not enough. These factors cause excess moisture resulting in decomposition, germination, or breakage of grain and seed. In these cases, these are discarded generating a large percentage of deficit and production losses.

The main focuses of grain loss are at the bottom of bulk warehouses, and silos, due to high humidity, the mass of the grain is compacted, generating fungi and preventing the proper functioning of equipment such as sweep auger or equipment unloading.

In addition, excess moisture compromises the storage structure, which eventually goes through the corrosion process, also contaminating grains and seeds, impairing the quality of the entire product. With the application of Marema Coatings QS PP 350 Polyurea at the base of the silos, water infiltration is prevented, the coating helps in the process of controlling the variables (temperature and humidity), solving these problems, preserving the quality of the silos grain and seed, crop productivity and, while still being an anti-corrosion coating, for the storage structure.

QS PP 350 Polyurea Protective Coating Application on flow wheighting system

Flow wheighting system are used for both loading and unloading grain on ships, trucks and wagons. Widely used in ports, calculates and indicates the subtotal and total flow (t / h) of the product transferred during the process.

In the case of ports, the passage of materials is continuous and large-scale, causing the grain, due to its impact and its abrasive content (rice, for example) to damage the metal substrate, wearing and puncturing it. This results in their frequent maintenance in a short time - we have cases where the substrate it's bored in 60 days of continuous use.

Large waste of both time and money are caused by this situation as the entire process needs to be interrupted to perform maintenance, leading to delays in loading or unloading the product.

Great costs are generated, of which we can mention:

1- Daily fine due to the fact that the ship is moored waiting for the cargo;

2- Delay in product billing;

3- Employees having to stop their activities;

4- Employees having to be relocated to perform the maintenance;

5- Maintenance by reworking the scales with the exchange of the metal substrate.

With the application of the QS PP 350 Polyuria (highly resistant to impact and sanding abrasion) the substrate is completely sealed, leaving it not in direct contact with the grain, thus preventing its early wear and thus considerably increasing its Shelf life - We have cases where we apply 13mm of the coating. After 4 years the expected wear would be 8 millimeters. During our quality control technical visit to the customer, wear of only 3mm was found, resulting in greatly reduced customer costs and increased productivity.

[caption id="attachment_3191" align="aligncenter" width="1014"] Picture: Marema Coatings[/caption]

Source: Marema Coatings

Picture: Marema Coatings[/caption]

Source: Marema Coatings

Comment Now