Cotton seed pressing and solvent extraction plant with capacity ranging from 30 t/d to 2,000 t/d

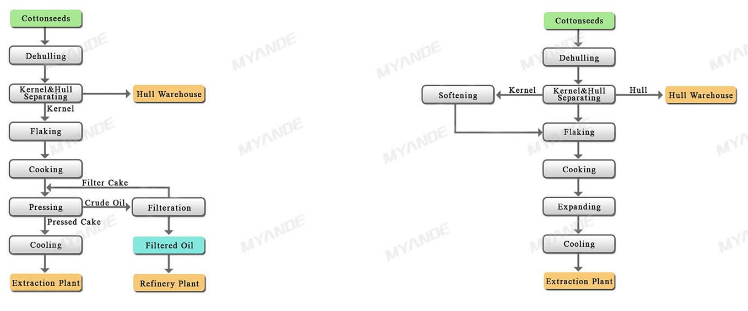

There are two kinds of processes. The first one is: Dehulling, Kernel and Hull Separation, Flaking, Cooking, Pressing, Oil Residue Separation. The second one is: Dehulling, Kernel and Hull Separation, Softening, Flaking, Cooking, Expanding, Cooling.

-By Myande Group |Source: Online/KSU

Comment Now