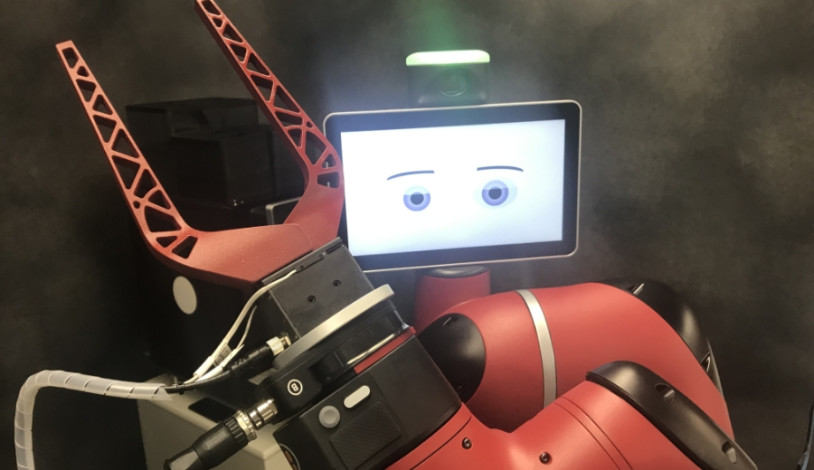

File Photo

The global collaborative robots demand is subjected to register a CAGR of 25.1%. The market revenue is likely to be valued at US$ 2.2 billion in 2023 and exhibit a revenue growth of US$ 20.5 billion by 2033.

Global Trends & Scopes Transforming the Collaborative Robots Market

SMEs are looking for automation to help them accomplish more with less and grow their operations in the face of manpower shortages, disruptive technology, and new commercial demands. SME automation allows businesses to remove time-consuming, repetitive, and possibly dangerous manual procedures, improve quality, and take on more work without incurring additional labor expenditures.

Collaborative robots (cobots) can assist industrial SMEs in introducing automated welding at a lower cost and providing an efficient approach to upskilling teams. OEM and automation integrator collaborative robot solutions combine dependable robot arms with a lightweight, simple-to-install control box. They are perfect for integrators, machine builders, and end users who require the control box to be integrated into the main control panel.

The e-Series cobots, developed by a certain market participant, are equipped with straightforward programming, diverse use, and an almost infinite list of addon possibilities. Regardless of your sector, business size, or product type, the e-Series may supplement production. This cobot was created with the future in mind, and it is intended to develop capabilities with enterprises. It takes on new jobs and discovers new applications so that the end user may constantly remain ahead of their competitors.

A type of intelligent product is another significant company's series of collaborative robots. It is designed for the visual guidance needed by the arm in an industrial automation situation. The device uses the arm as its core and combines a unique vision controller, special vision software, an industrial camera, and a light source module to allow users for completing vision hardware configuration quickly on-site. It also meets the arm's visual guidance needs in a variety of complex settings.

Key players have been creating robots for 50 years, with the primary goal of enhancing the productivity of their own vehicle component production operations. Key players have just unveiled a new collaborative robot that is human-friendly, tiny, and portable.

As the lifecycles of medical and cosmetic products shorten, collaborative automation improves production agility. Key players' robot arms may be employed to increase productivity and maintain constant quality before being easily redeployed for new product lines. Throughout the business, cobots are used to maintain machines and conveyors, accurately assemble gadgets and goods, and prepare and package things into blister packs, cartons, or pallets.

Historical Outlook versus Future Projections for the Collaborative Robots Market

In the global market, collaborative robot sales recorded stellar growth of 50.4% CAGR from the period 2014 to 2021. This market is anticipated to record a 26% CAGR rate from 2022 to 2029 according to FMI. There is an increase in the use of these robots for several industrial applications including material handling, inspection, and assembly/disassembly due to the attribute. Furthermore, there are a few other factors anticipated to fuel the demand for collaborative robot sales such as the increasing investments in assembly automation and the growing adoption from both small and medium enterprises. The market revenue is estimated to grow to US$ 20.5 billion by 2033.

High Initial Costs & Other Restraints with Market Opportunities

The high initial expenses of robots preclude most businesses from fully automating their processes using robots. The average selling price of a cobot ranges from US$ 25,000 to US$ 50,000, not including installation charges. Furthermore, there is a training expense connected with the robots, which limits the operators' willingness to integrate robots into their operating lines. The robotics market is hampered by the slow adoption of collaborative robotic systems by small and medium-sized businesses. High labor expenses, on the other hand, are expected to fuel the collaborative robot market throughout the projection period.

Robots are being used by numerous manufacturing activities around the area as technology progresses and applications become broader and adaptable. Collaborated robotics for automotive applications has seen a significant increase in recent years, owing to the growth of automotive plants in prominent economies of Asia Pacific such as China, India, and Vietnam, as well as increased demand for automotive robots from automakers in North America. Several famous automakers have deployed cobots on their manufacturing floors to do a variety of tasks such as welding, automobile painting, and assembly line operations.

Newbies are Catching Up with Key Players with Innovative Strategies: Start-up Economy

Start-up companies are participating in robotics technology alongside key industry players to contribute to the global collaborative robots market growth:

Ready Robotics - It is a manufacturer of collaborative robots as well as an operating system for controlling them. Its portfolio includes TaskMate, a modular, plug-and-play robotic arm coupled to a mobile base that can be moved about the plant and used to automate risky and repetitive activities. It can also save jobs for later and distribute them in minutes thanks to its own translation mechanism. The firm also provides an operating system that allows the user to operate the robot by chaining construction pieces together into flowcharts. Furthermore, it provides robots as a service, allowing firms to rapidly integrate and deploy a robotic automation system into production for a low monthly price.

Yang Tian Technology - It provides collaborative robotic products for industrial use. It offers a line of collaborative robots that claim to have a 6-DOF robot 6 modular structure design, combining hollow series arms and internal wiring to build light modular robots. It can be utilized in electronics, food, equipment, medicine, the military, automotive, and other sectors for handling, assembling, polishing, coating, monitoring, and screwing. In addition, the business offers a line of 5DoF parallel robots for material handling in industries.

ISYBOT - It develops collaborative robots for industrial purposes. The company has developed robots with three servo axes, a payload capacity, and a range of motion. The robot operates in four modes: help, restitution, parallelization, and teleoperation. The firm also offers the opportunity to hire robots for four to twelve months. Applications include material handling and project completion.

Key Companies Revamping the Collaborative Robots Market Space

Due to the engagement of multiple established competitors, the collaborative robots market share is very competitive. Firms in the collaborative modular robotics industry frequently employ organic development strategies such as product releases and approvals. Market companies are focusing on expanding their presence through acquisitions, expansions, product approvals, and launches in order to leverage market growth potential.

Latest Developments:

In December 2020, to make programming its single-arm YuMi cobot easier, ABB Ltd. launched "Wizard Easy Programming," a block-based programming interface. The business also stated that it intends to make its cobots easier to set up for individuals who do not know how to program, thereby lowering the entry barrier.

In March 2020, Universal Robots debuted UR+ application kits at MODEX 2020 to make Cobot deployment easier for small, medium, and large organizations, as well as unique solutions that highlighted the usage of cobots to automate difficult-to-staff processes such as palletizing and piece-picking.

In August 2020, in India, Mitsubishi Electric Corporation introduced the MELFA ASSISTA line of collaborative robots. They have safety features including collision detection and rigorously adhere to the international safety and robotic standards ISO 10218-1 and ISO/TS15066. Following a successful global launch, the business offered these collaborative robots to the Indian market in order to gain a competitive advantage in the Indian industrial sector.

These insights are based on a report on

Collaborative Robots Market

by Future Market Insights.

Source: Email/GFMM

Comment Now