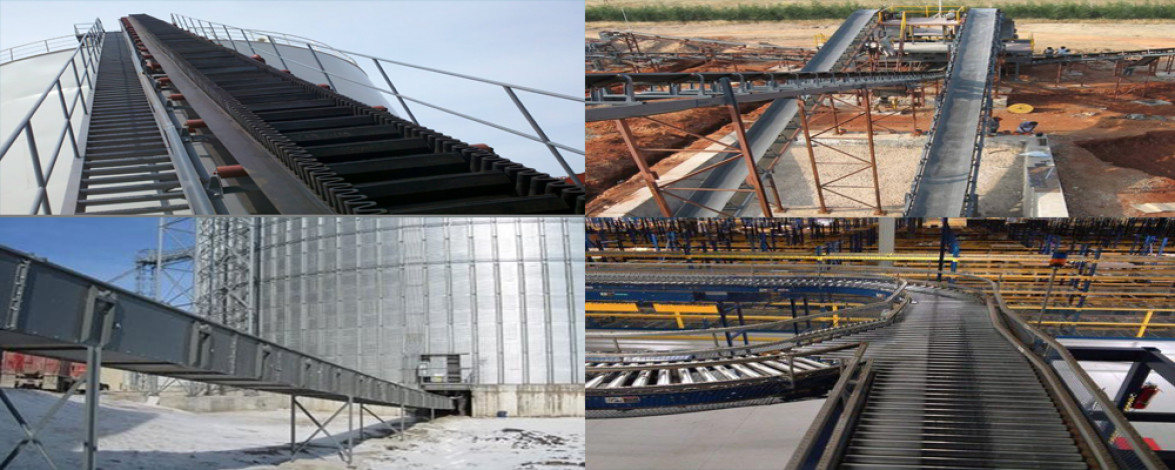

The belt conveyor is one of the best options for bulk materials handling equipment. It can continuously transport materials from one place to another place in industries or in some other sector. A conveyor belt is part of the conveyor system that plays an important role in carrying material to and fro. This system is made up of a conveyor belt rotating about the two or more pulleys. Belt conveyor consist of conveyor belt, pulley, idlers, frame, tension devices, driving unit, protection switches and other components etc. Belt conveyor is widely used in mining, metallurgy, port, cement, grain, chemical and other industries. Types of a Conveyor system There are various types of conveyor systems available in the world market which can be selected as per the requirement.

Gravity-roller conveyors: They are using the concept of gravitational force while conveying any product or material. In this conveyor system, the frame installed is inclined slightly in order to move any product down in direction of gravity flow. It consists of a sequence of corresponding rollers that is attached to the metal frame supported at the end. The material or product has to roll manually on the system. The main benefit of using gravity roller conveyors is it is cost effective yet simple technology.

Belt conveyors system: They can be used for wide range of product handling varying from lightweight to heavy weight products like grain, sand, coal, etc. and for transferring them from one point to another point. It mainly consists of a belt that forms a loop like structure and it slides on roller or pulley depending upon the load behavior and is operated using an electric motor. The belt used can be made up rubber or plastic.

Slat conveyors: They are mainly formed of a chain which is driven by a motor and used for moving product or object. They are widely used in food and pharmaceutical industry for carrying bottles and cans. The chains used can be made from steel or plastic depending upon the nature of the load. Large slat conveyor system is used for moving heavy weight product are used in big industries or storehouse whereas small slat conveyor is used for moving lightweight product and can be used in small or medium size industries. They are suitable for the production lines that comprises of any twist and loop. Their main benefit is them is that easy installation, low maintenance and cost-effective.

Bucket conveyors: They consist of a number of the bucket that is connected to the endless chain or belts used for carrying material in horizontally, vertically or sloppy path. The bucket remains in its holding position until the product discharge takes place.

Key Factors While Selecting a Conveyor System

There are a number of factors that must be kept in mind while selecting a conveyor system. Let us see some of the key factors below-

Key Factors While Selecting a Conveyor System

There are a number of factors that must be kept in mind while selecting a conveyor system. Let us see some of the key factors below-

Technical Specifications of Belt Conveyor :

Belt Width Up to 2.4m Belt Length 3,000m + Capacity > 8,000 m³/h Belt speed Up to 6.0m/s Max Incline Maximum 25º Drive Type Motorized pulley Geared motor unit Motor+fluid coupling+gear box | Belt Options Antistatic| Fire resistant | Oil resistant | Hard wearing | corrosion resistant Tension Unit Below 100m – screw type tail tension unit | Above 100m - gravity tension unit or car type tension unit Protection Switches Speed switch | Belt Sway Switches | Pull-cord switch | Blockage sensor Construction Materials Conveyor case and internals - stainless or coated mild steel | Conveyor support structure - galvanized mild steel. Conveyed Materials Wet or dry bulky materials in the form of crumbs, grains, pellets, shreds, dust, powder, flake, or crushed products of bio-matter, sludge and aggregate.

Benefits of Using a Conveyor system:

Comment Now