[caption id="attachment_4096" align="aligncenter" width="1014"] Picture: Collected[/caption]

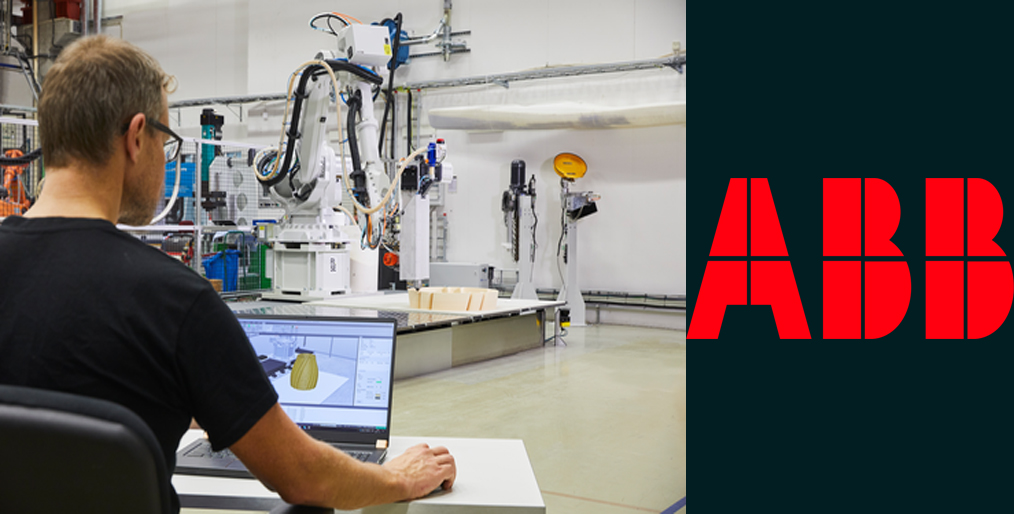

GFMM desk: ABB has introduced the 3D printing capability of its PowerPack software with its RobotStudio simulation and offline programming software, which gives users the ability to program ABB robots for additive manufacturing.

While traditional 3D printing methods require programming the printing paths—which involves plotting millions of points and trajectories—ABB’s PowerPac software can translate any standard slicer software design into ABB’s simulation environment and robot code. This means an operator can progress from the CAD design stage to final modeling of a product in roughly half an hour, according to ABB.

ABB says PowerPac will support a variety of processes, such as welding and printing with granules or concrete, making it well suited for low-volume, high-mix printing.

“With our new 3D Printing software, we are offering customers a faster and more streamlined 3D printing process. Coupled with the high performance of our robots, this means manufacturers can now produce high-quality 3D printed objects for a variety of industrial applications more efficiently,” said Steven Wyatt, head of portfolio and digital at ABB Robotics and Discrete Automation.

About ABB, it’s a Swiss-Swedish multinational corporation headquartered in Zurich, Switzerland, operating mainly in robotics, power, heavy electrical equipment, and automation technology areas. It is ranked 341st in the Fortune Global 500 list of 2018 and has been a global Fortune 500 company for 24 years.

Source: Online/SZK

Picture: Collected[/caption]

GFMM desk: ABB has introduced the 3D printing capability of its PowerPack software with its RobotStudio simulation and offline programming software, which gives users the ability to program ABB robots for additive manufacturing.

While traditional 3D printing methods require programming the printing paths—which involves plotting millions of points and trajectories—ABB’s PowerPac software can translate any standard slicer software design into ABB’s simulation environment and robot code. This means an operator can progress from the CAD design stage to final modeling of a product in roughly half an hour, according to ABB.

ABB says PowerPac will support a variety of processes, such as welding and printing with granules or concrete, making it well suited for low-volume, high-mix printing.

“With our new 3D Printing software, we are offering customers a faster and more streamlined 3D printing process. Coupled with the high performance of our robots, this means manufacturers can now produce high-quality 3D printed objects for a variety of industrial applications more efficiently,” said Steven Wyatt, head of portfolio and digital at ABB Robotics and Discrete Automation.

About ABB, it’s a Swiss-Swedish multinational corporation headquartered in Zurich, Switzerland, operating mainly in robotics, power, heavy electrical equipment, and automation technology areas. It is ranked 341st in the Fortune Global 500 list of 2018 and has been a global Fortune 500 company for 24 years.

Source: Online/SZK

Comment Now