[caption id="attachment_2912" align="aligncenter" width="1014"] Picture: Rostfrei Steels[/caption]

Rostfrei Steels Pvt. Ltd. is a well-known name in India for large liquid storage tanks and grain storage silos. Rostfrei Steel Pvt. Ltd. is an ISO 9001 company and is operational since 2004. Since 2004 Rostfrei Steels has completed more than 8000 installations worldwide in approx. 25 countries.

Being an Indian company the major objective of Rostfrei Steels was to find a very effective grain storage solution for tropical and sub-tropical regions of India and another objective was to find a cost effective solution for Paddy (Unshelled Rice) storage since India is second largest country in Rice Production and paddy is difficult grain to store in metallic silos due to its high silica content.

Finally, the search ended with Zincalume Steel Silos grade AZ-150 and Colorbond Steel Silos (AZ-200).

Both these steels perform better in tropical and sub-tropical regions and are very good for storage of abrasive, high moisture and fragile grains like paddy. Moreover Zincalume steel and Colorbond Steel Silos performs far better than conventional GI Steel silos in India like climates. Colorbond Steels has advantage that one can choose any color to match existing color theme of customer’s factory, however Zincalume steel silos are more cost effective.

Picture: Rostfrei Steels[/caption]

Rostfrei Steels Pvt. Ltd. is a well-known name in India for large liquid storage tanks and grain storage silos. Rostfrei Steel Pvt. Ltd. is an ISO 9001 company and is operational since 2004. Since 2004 Rostfrei Steels has completed more than 8000 installations worldwide in approx. 25 countries.

Being an Indian company the major objective of Rostfrei Steels was to find a very effective grain storage solution for tropical and sub-tropical regions of India and another objective was to find a cost effective solution for Paddy (Unshelled Rice) storage since India is second largest country in Rice Production and paddy is difficult grain to store in metallic silos due to its high silica content.

Finally, the search ended with Zincalume Steel Silos grade AZ-150 and Colorbond Steel Silos (AZ-200).

Both these steels perform better in tropical and sub-tropical regions and are very good for storage of abrasive, high moisture and fragile grains like paddy. Moreover Zincalume steel and Colorbond Steel Silos performs far better than conventional GI Steel silos in India like climates. Colorbond Steels has advantage that one can choose any color to match existing color theme of customer’s factory, however Zincalume steel silos are more cost effective. Zincalume Steel

ZINCALUME Steel like Galvanised steel is a metal coated steel but it has Alloy coating of 55% aluminium, 43.4% zinc and 1.6% silicon which is carried out at 600 Deg C. Zincalume is the best material for long-term storage of grains as it has Excellent Thermal Reflectivity, Better Corrosion Resistant, Lightweight and Stronger than conventional Galvanised steel material.

Problems associated with GI Steel Silos

The biggest problem is that the average service life of GI Steel Silos is very less in tropical and subtropical regions. GI Steel have metal coating of 99.7% Zinc over mild steel base metal which is carried out at 450 Deg C. Zinc Coating saves mild steel from getting corroded by providing galvanic protection. Zinc, however reacts with atmospheric oxygen in the presence of humidity and form Zinc Oxide. Zinc protects base metal mild steel by gradually sacrificing itself, which means by converting itself to Zinc Oxide. Eventually with the passage of time whole of zinc coating gets sacrificed and base metal mild steel is exposed and thereafter corrosion of base metal is very fast.

Since zinc reacts with atmospheric oxygen only in the presence of humidity in the air. Wherever the humidity is more the reaction is fast and wherever it is less reaction is slow. Warmer air has more capability to retain moisture and colder air has less capability to retain moisture. Hence GI performs better in colder climates than in warmer climates hence more popular in countries where the climatic is colder most of the time.

In tropical and sub-tropical regions since the air is warm and humid, GI does not perform to its expectations.

Average Service Life of of GI Steel silos in tropical and sub-tropical regions is as mentioned in the table below;

Zincalume Steel

ZINCALUME Steel like Galvanised steel is a metal coated steel but it has Alloy coating of 55% aluminium, 43.4% zinc and 1.6% silicon which is carried out at 600 Deg C. Zincalume is the best material for long-term storage of grains as it has Excellent Thermal Reflectivity, Better Corrosion Resistant, Lightweight and Stronger than conventional Galvanised steel material.

Problems associated with GI Steel Silos

The biggest problem is that the average service life of GI Steel Silos is very less in tropical and subtropical regions. GI Steel have metal coating of 99.7% Zinc over mild steel base metal which is carried out at 450 Deg C. Zinc Coating saves mild steel from getting corroded by providing galvanic protection. Zinc, however reacts with atmospheric oxygen in the presence of humidity and form Zinc Oxide. Zinc protects base metal mild steel by gradually sacrificing itself, which means by converting itself to Zinc Oxide. Eventually with the passage of time whole of zinc coating gets sacrificed and base metal mild steel is exposed and thereafter corrosion of base metal is very fast.

Since zinc reacts with atmospheric oxygen only in the presence of humidity in the air. Wherever the humidity is more the reaction is fast and wherever it is less reaction is slow. Warmer air has more capability to retain moisture and colder air has less capability to retain moisture. Hence GI performs better in colder climates than in warmer climates hence more popular in countries where the climatic is colder most of the time.

In tropical and sub-tropical regions since the air is warm and humid, GI does not perform to its expectations.

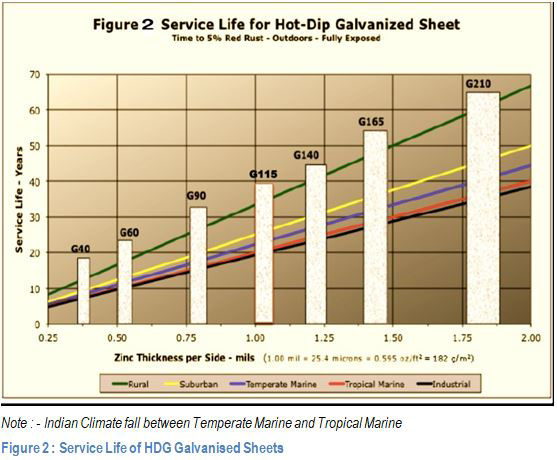

Average Service Life of of GI Steel silos in tropical and sub-tropical regions is as mentioned in the table below; Graph below displays how GI performs in Rural, Sub-urban, Temperate Marine and Tropical Marine atmospheres

Graph below displays how GI performs in Rural, Sub-urban, Temperate Marine and Tropical Marine atmospheres

Rostfrei Make Zincalume Silos solves the corrosion problems

ZINCALUME Steel has Alloy coating of 55% aluminium, 43.4% zinc and 1.6% silicon by weight. Since Aluminium is a lighter metal hence volumetrically it occupies approximately 80% of the volume, and hence aluminium helps to protect zinc coming directly in contact with atmospheric humidity and oxygen. Thus, Zincalume has double protection - Barrier protection of Aluminium and Galvanic protection of Zinc. Aluminium is protecting Zinc and Zinc is further protecting Base metal.

Advantages of Rostfrei Make Zincalume Steel Silos

Zincalume Steel Silos provide following benefits that no other grain silo can provide so efficiently

Rostfrei Make Zincalume Silos solves the corrosion problems

ZINCALUME Steel has Alloy coating of 55% aluminium, 43.4% zinc and 1.6% silicon by weight. Since Aluminium is a lighter metal hence volumetrically it occupies approximately 80% of the volume, and hence aluminium helps to protect zinc coming directly in contact with atmospheric humidity and oxygen. Thus, Zincalume has double protection - Barrier protection of Aluminium and Galvanic protection of Zinc. Aluminium is protecting Zinc and Zinc is further protecting Base metal.

Advantages of Rostfrei Make Zincalume Steel Silos

Zincalume Steel Silos provide following benefits that no other grain silo can provide so efficiently

Comment Now