The proper performance of all the processes involved in the post-harvest handling of grains and oilseeds, which includes their storage, transport, and post-harvest conditioning, is essential to maintain the highest quality. Adequate conservation measures are essential since deterioration during storage can be very rapid due to the effects of grain respiration.

FACTS

* The current world population is expected to reach 10.5 billion by 2050.

* This increase translates into 33% more human mouths to feed.

* Food availability and accessibility can be increased by increasing production, improving distribution, and reducing losses.

* Crop production contributes a significant proportion of typical incomes in certain regions of the world (70 percent in Sub-Saharan Africa).

* In some Sub-Saharan African countries, the post-harvesting losses because of bad storage can reach sometimes 37-40 %.

* The PHL "post-harvest grain losses" can be qualitative and quantitative.

INITIAL FACTORS OF HARVESTING

The proper performance of all the processes involved in the post-harvest handling of grains and oilseeds, which includes their storage, transport, and post-harvest conditioning, is essential to maintain the highest quality. Adequate conservation measures are essential since deterioration during storage can be very rapid due to the effects of grain respiration, which can cause the development of fungi and insects that proliferate easily in optimal humidity and temperature conditions.

The three major factors affecting the grain storage are:

* Moisture content

* Temperature

* Storage period

Storage technologies don't do anything by themselves. Proper management has to be done by the owner.

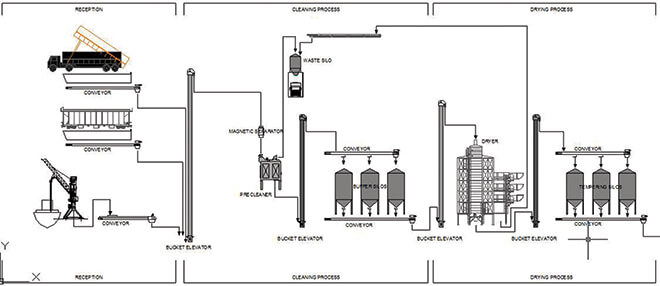

RECEPTION

Before unloading: Take samples for measuring the temperature and moisture content. The grain laboratory will easily analyze the grain conditions.

During unloading: it is recommendable an aspiration system. In some countries is even mandatory.

* Some aspects regarding this system should be considered:

* Pit intake dimension

* Installed inside a building/cover

* Receiving capacity

* Aspiration volume

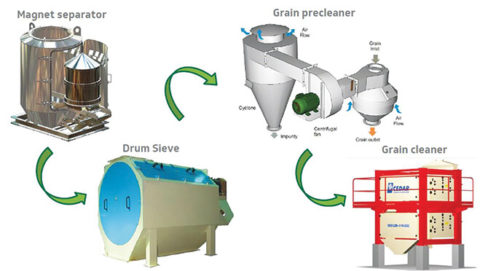

CLEANING PROCESS

Cleaning is the process that removes foreign particles from the bulk.

BUFFER SILOS

After the cleaning process, buffer silos should be installed. Why? Because the drying process tends to be the bottleneck in every single storage plant.

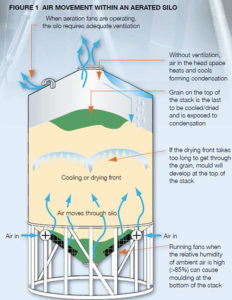

Ventilation system: This should be calculated depending on the grain we are going to store.

Exhaust fans: to prevent condensation.

Overhead cone: This system allows a FIFO flow system, guaranteeing that all grain will remain inside the silo for the same period.

DRYING PROCESS

Drying is the process that reduces grain moisture content (MC) to a safe level for storage.

Initial factor: at harvest time the grain contains high MC.

Drying process: Using the ambient air with a low relative humidity or heating air. This will evaporate the moisture from the grain.

Drying rate and temperature:

* Seed, should never exceed 43 degrees Celcius.

* Grain processed: should never exceed 60-65 degrees Celcius.

Recommendations:

* Dryer election will depend on your technical requirements.

* Get the knowledge from the dryer manufacturer: training.

* Clean before dry. Impurities in grain bulk reduce the airflow and make it a nonhomogeneous flow creating priority paths.

* Do not mix wet and dry grain.

* Take samples: control the moisture content and temperature in the drying process.

* Experience in the previous drying will lead you to increase the drying efficiency.

* Dry a maximum of 5% of the moisture content at a time and then leave the grain to rest for a minimum of 8-12 hours.

TEMPERING SILOS

Tempering silos are used to cool down the grain and make the bulk grain uniform in terms of temperature and MC. Depending on the storage capacity, we can cool down the grain either using a tempering silo or in the final storage system. How to do ventilation at this point?

Ventilation system: centrifugal fans or chillers.

Exhaust fans: to prevent condensation.

Overhead cone: This system allows a FIFO flow system, guaranteeing that all grain will remain in the same period inside the silo.

VENTILATION SYSTEM

Because of the tropical climate of some countries, ventilation systems using centrifugal fans are no longer sufficient, and cooling systems are necessary. Coolers or centrifugal fans can be used in steel silos, concrete silos, and warehouses.

Moisture content is required for safe storage for different storage periods.

Considerations:

* Grain column height.

* Priority ventilation paths.

* Ventilation grills.

* Exhaust fans.

TEMPERATURE MONITORING SYSTEM

The simple and accurate device is made up of three elements: a control center, probes, and an electronic module of multiplexation.

Traditional methods of grain storage:

Warehouse - gunny bags stacked

CAP- Covered and Plinth in open space

Silos- Bulk grain stored in silos: Concrete silos, Galvanized steel, Silo Bag

-By Silos Spain

Source: Online/GFMM

Comment Now