The white material of the horizontal rice milling machine enters the white room from one end and flows out from the other end of the white room. Under the action of the high-speed rotating roller, the rice grains are ground white in the flowing state. The motion of the rice fluid in the white roller can be regarded as a horizontal spiral around the roller. The flow direction of the rice flow in the white roller chamber is perpendicular to the gravity direction of the rice flow. This type of rice mill has the following technological characteristics:

1.1 Good White Uniformity The white uniformity of rice grains is related to the structure form of the roller, the material of the roller surface, the motion parameters of the roller, and more importantly, the motion state of the rice grains in the white chamber. Rice grain white in rolling, its white uniformity is the best. In the horizontal rice mill, the motion of rice grains in the white roller is obtained from the roller. Under the action of the high-speed rotating roller, the rice grains roll sharply. The rice grains both roll along its long axis and turn over along its short axis (see Figure 1). The rice grains are in a state of irregular and rapid rolling motion in the white roller room. It is this irregular sharp tumbling that makes every point of the rice grain have the opportunity to be rubbed off by grinding and achieve a good effect of uniform grinding white.

1.2 Broken rice is easy to be produced in the process of grinding white

In the process of white grinding, influenced by the gravity of the rice fluid itself, the density of the rice fluid in the cross-section of the white grinding chamber is uneven. The density of the rice fluid in the lower part of the white grinding chamber is high, while the density in the upper part is low. Therefore, in the lower part of the white grinding chamber, the rice grains are subjected to great grinding pressure, which is easy to produce broken rice. In the upper part of the white grinding chamber, due to the small density of rice grains and the large gap between rice grains, the rapid collision between the rice grains and the components of the white grinding chamber under the action of the high-speed rotating roller is also easy to produce broken rice.

In the design of a horizontal rice milling machine, it is required that the rolled rice husks should be discharged from the bran sifter in a 360° circle towards the grinding chamber. In the process of production, due to the gradual accumulation of rice bran discharged in the process of grinding, the screen holes are blocked or the screen size is reduced, and the effective bran discharging area is smaller than the designed bran discharging area. In the process of production, the bran discharging screen surface is often not cleaned in time, resulting in the rice husk under the grinding can not be discharged from the grinding room in time, and the rice contains more bran powder. Of course, the bran removal of horizontal air jet rice mills does not exist in the above phenomenon. If in production, before and after the shift, the operator strengthens the cleaning of the bran sieve, can solve the problem.

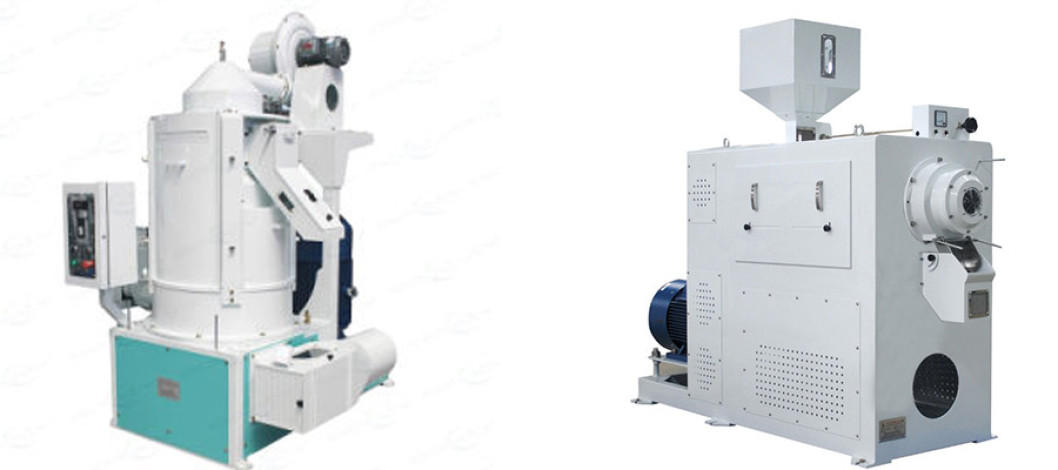

According to different feeding and discharging modes, vertical rice milling machines can be divided into two kinds: vertical rice milling machines with top feeding and bottom discharging and vertical rice milling machines with bottom feeding and top discharging, which are discussed separately below.

2.1 The white material of the vertical rice mill enters the white room from the top of the rice mill. Under the combined action of the roller and the gravity of the rice fluid, the rice is white in the flow and discharged from the lower part of the white room. The motion of the rice fluid in the white roller can be regarded as a vertical spiral from top to bottom around the roller. The direction of the rice flow in the grinding chamber is the same as that of its own gravity. The machine shows the following technological characteristics:

2.1.1 Low power consumption in the rice milling process, rice fluid moves from top to bottom. Affected by gravity, the rice grains have the ability to transport themselves from top to bottom, thus reducing the power consumption of the rice machine. The power consumed by the roller in the rice mill is mainly used for the white rolling of rice grains. Unlike horizontal rice mills and vertical rice mills with lower feed and upper discharge, the power consumed in the rice roller is not only used for white grinding of rice grains, but also for axial conveying of rice grains.

2.1.2 Less broken rice produced in the process of grinding white, in the process of grinding white, the rice grain fluid density on the cross-section of the machine grinding white room is uniform, so the white grinding pressure is uniform, producing less broken rice, produced less broken rice, rice bran discharged pure. Compared with the horizontal rice roller, the rice bran is basically no small broken rice, and the content of the millet rotary is very small. A separate chaff separation process may be considered in production.

Comment Now