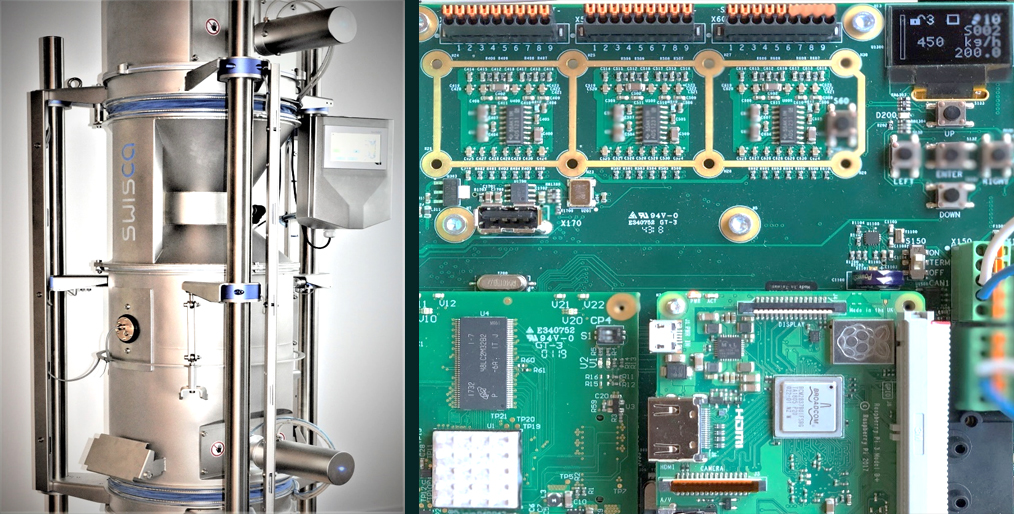

[caption id="attachment_3827" align="aligncenter" width="1014"] Picture: Heinz Brand[/caption]

Introduction

Digitizing data and making data available for electronic data processing is a trend in the milling industry. Fewer errors and falsifications are occurring or errors can be excluded when moisture, mass flow, weight and density are measured at a single point in real time and digitally processed. In the operational processes of a mill operation, digitization enables an increase in efficiency and thus an improvement in its economic efficiency. The data generated in digital form with multi-functional measuring systems are also suitable for optimizing quality and processes online.

[caption id="attachment_3828" align="aligncenter" width="414"]

Picture: Heinz Brand[/caption]

Introduction

Digitizing data and making data available for electronic data processing is a trend in the milling industry. Fewer errors and falsifications are occurring or errors can be excluded when moisture, mass flow, weight and density are measured at a single point in real time and digitally processed. In the operational processes of a mill operation, digitization enables an increase in efficiency and thus an improvement in its economic efficiency. The data generated in digital form with multi-functional measuring systems are also suitable for optimizing quality and processes online.

[caption id="attachment_3828" align="aligncenter" width="414"] Figure 1: The parameters of flaking and drying are checked in real time and corrected if necessary.[/caption]

Multi-functional Measuring Systems

In the milling industry, accurate weight measurement has gained in importance. The production process and the expected product quality define the required accuracy and measurement parameters for process monitoring and quality assurance.

[caption id="attachment_3829" align="aligncenter" width="215"]

Figure 1: The parameters of flaking and drying are checked in real time and corrected if necessary.[/caption]

Multi-functional Measuring Systems

In the milling industry, accurate weight measurement has gained in importance. The production process and the expected product quality define the required accuracy and measurement parameters for process monitoring and quality assurance.

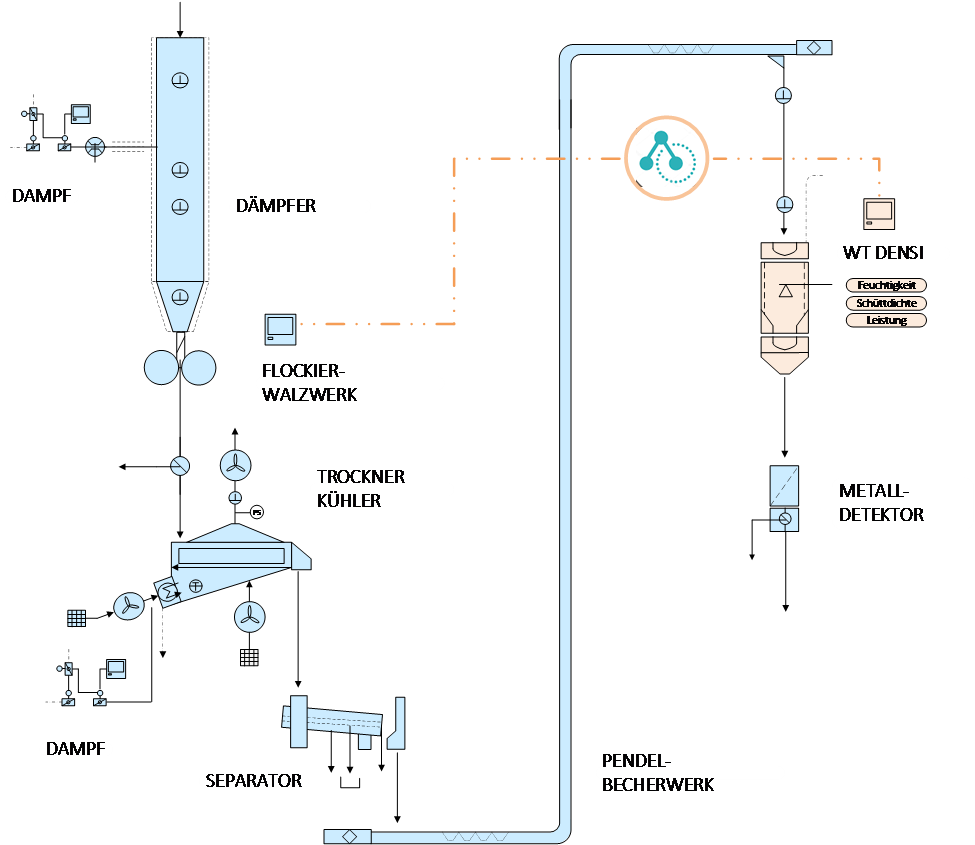

[caption id="attachment_3829" align="aligncenter" width="215"] Figure 2: Multi-functional weighing systems not only measure several measured variables simultaneously, but also save energy costs because compressed air is no longer required.[/caption]

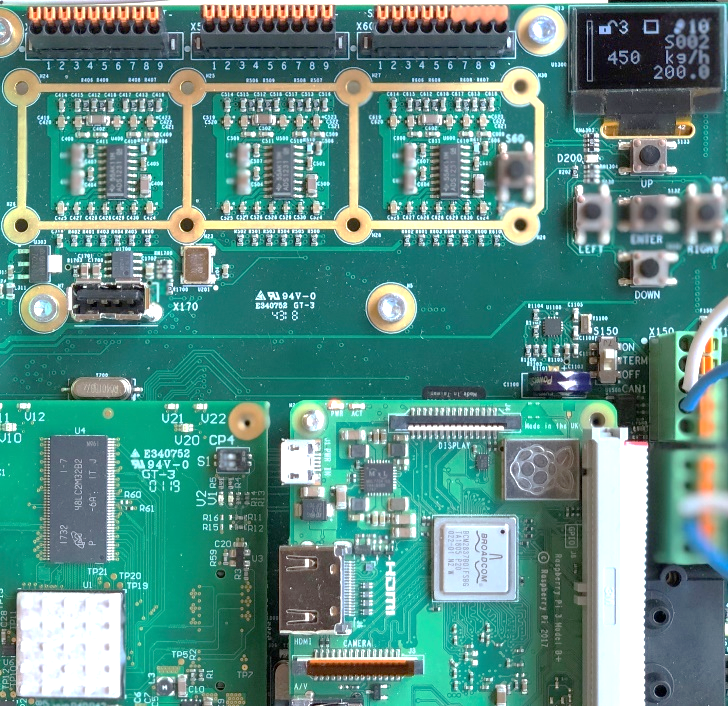

In addition to recording mass flow and weight, multi-functional weighing systems can also measure and digitally process humidity, temperature and density at a single point in real time. The cost and error of real-time digital measurements is less than the time-consuming process of manual sampling, analysis and evaluation in the lab and manual process control. Cloud solutions and remote maintenance enable optimal data access and use for internal process control and product trace-ability. Ethernet-based field-bus modules ProfiNet and Ether-Net/IP or Profibus and the RS 485 interface are used for this purpose.

[caption id="attachment_3830" align="aligncenter" width="297"]

Figure 2: Multi-functional weighing systems not only measure several measured variables simultaneously, but also save energy costs because compressed air is no longer required.[/caption]

In addition to recording mass flow and weight, multi-functional weighing systems can also measure and digitally process humidity, temperature and density at a single point in real time. The cost and error of real-time digital measurements is less than the time-consuming process of manual sampling, analysis and evaluation in the lab and manual process control. Cloud solutions and remote maintenance enable optimal data access and use for internal process control and product trace-ability. Ethernet-based field-bus modules ProfiNet and Ether-Net/IP or Profibus and the RS 485 interface are used for this purpose.

[caption id="attachment_3830" align="aligncenter" width="297"] Figure 3: State-of-the-art Control with Field-bus or Profibus and independent Web Server for Cloud Solutions and Remote Maintenance.[/caption]

Summary

The trend towards process optimization with multi-functional weighing systems through the measurement of moisture, mass flow, weight, temperature and density in the mill industry not only saves costs and supports the miller in his work. Reasonable digitization optimizes the process control and thus the work of the operating personnel.

–By Dipl. Ing. Heinz Brand - Appenzell / Schweiz,

Source: Online/SZK

Figure 3: State-of-the-art Control with Field-bus or Profibus and independent Web Server for Cloud Solutions and Remote Maintenance.[/caption]

Summary

The trend towards process optimization with multi-functional weighing systems through the measurement of moisture, mass flow, weight, temperature and density in the mill industry not only saves costs and supports the miller in his work. Reasonable digitization optimizes the process control and thus the work of the operating personnel.

–By Dipl. Ing. Heinz Brand - Appenzell / Schweiz,

Source: Online/SZK

Comment Now