[caption id="attachment_3885" align="aligncenter" width="1014"] Picture: Heinz Brand[/caption]

Picture: Heinz Brand[/caption]

Whitepaper # Swisca #Innovation # FlourMilling # FoodProcessing

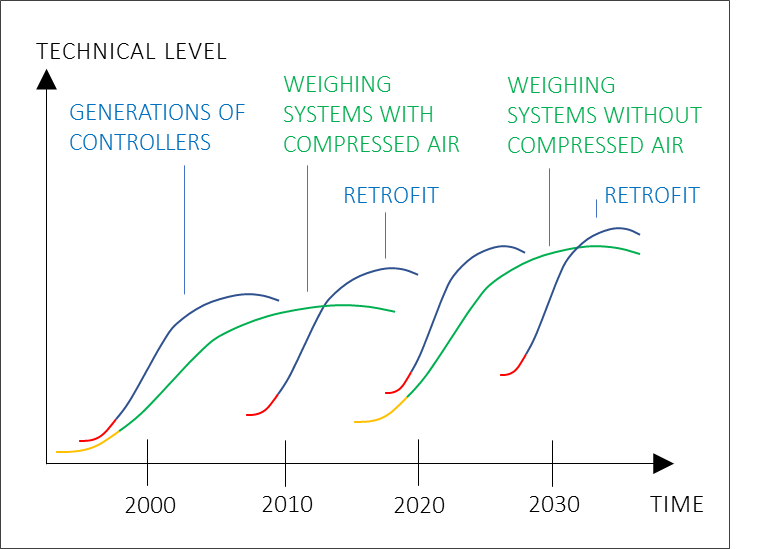

Figure 1: Short technology lifetimes of control generations for weighing systems have a decisive influence on the operational implementation of digitization in the mill industry.[/caption]

Figure 1: Short technology lifetimes of control generations for weighing systems have a decisive influence on the operational implementation of digitization in the mill industry.[/caption]

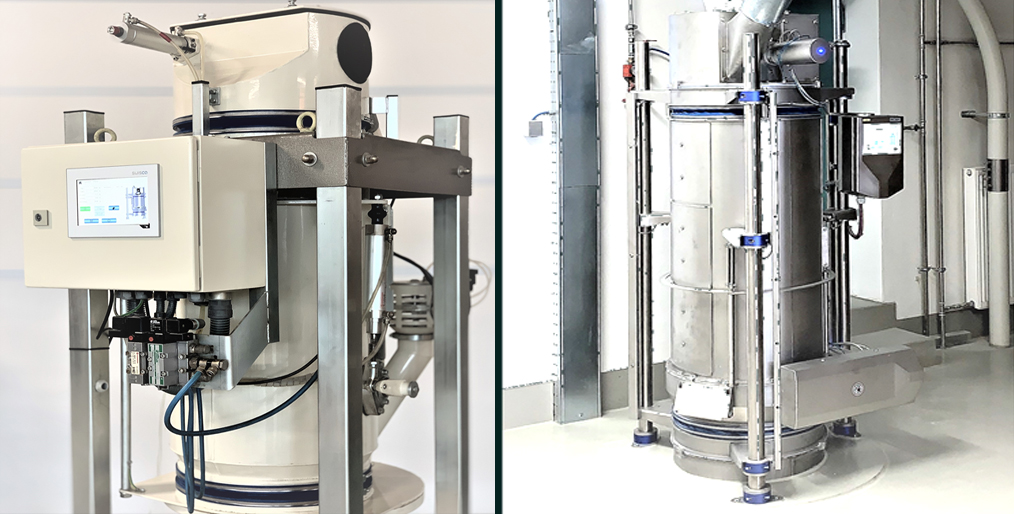

Figure 2: Appropriate maintenance, scale service and control retrofits enable IoT connectivity in a sustainable and economic manner and extend the lifetime of scales in the milling industry.[/caption]

Outdated control generations lack connectivity to a field-bus or the ability to connect to the Internet to take advantage of remote maintenance and cloud solutions. For appropriate digitization, data must be accessible and freely usable. Cloud solutions and remote maintenance enable optimal data access and use for internal process control and product trace-ability. Modern scale controls are equipped with a web server module and touch screen, robust and reliable.

[caption id="attachment_3888" align="aligncenter" width="420"]

Figure 2: Appropriate maintenance, scale service and control retrofits enable IoT connectivity in a sustainable and economic manner and extend the lifetime of scales in the milling industry.[/caption]

Outdated control generations lack connectivity to a field-bus or the ability to connect to the Internet to take advantage of remote maintenance and cloud solutions. For appropriate digitization, data must be accessible and freely usable. Cloud solutions and remote maintenance enable optimal data access and use for internal process control and product trace-ability. Modern scale controls are equipped with a web server module and touch screen, robust and reliable.

[caption id="attachment_3888" align="aligncenter" width="420"] Figure 3: State of the art weighing systems with servo drives are also saving energy costs because no compressed air is required.[/caption]

Figure 3: State of the art weighing systems with servo drives are also saving energy costs because no compressed air is required.[/caption]

Comment Now